DIN7513 cutting thread self-tapping bolt introduction:

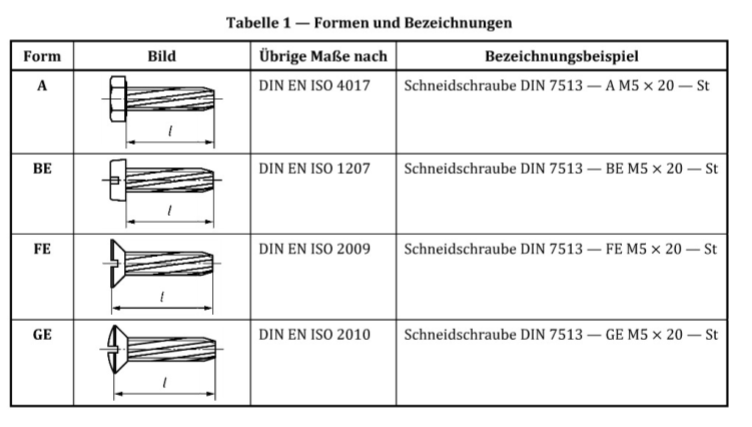

According to the head type :DIN7513(A) hexagonal head, DIN7513(BE) pan head, DIN7513(FE) countersunk head, DIN7513(GE) half countersunk head.

Different from ordinary bolts: Relative to ordinary bolts, DIN7513 thread itself has a scraping groove to facilitate chip removal and cutting.

Application scenarios of tapping bolt with cutting thread:

Scenario 1: It can be used for electrophoresis, spraying and other products that easily affect the size, which can significantly improve the assembly quality and assembly efficiency.

After coating or coating surface treatment, the gap between the internal and external threads is significantly reduced to a tight fit state due to the increased coating thickness. For example, when assembling with ordinary mechanical bolts, it is not easy to screw in smoothly; it is easy to cause deflection or jamming, which increases the difficulty of assembly, reduces assembly efficiency and assembly quality, and also brings defects and safety hazards to the product.

The research and development of cutting thread self-tapping screws can effectively solve this problem. The cutting grooves on the thread surface form an axial cutting edge with the thread. When the bolt is screwed into the mounting hole, the bolt rotates under the action of the screw-in force, and the cutting edge will prevent the mud or paint of the paint from being discharged out of the hole through the scraping groove, and at the same time extend into the mounting hole through the thread. Continuously rotate the bolt to completely remove the paint sludge in the mounting hole under multi-blade cutting until the bolt is completely assembled into the mounting hole.

Scenario 2: Similar to the usage scenario of flat-tail self-tapping screws

It is mainly used on non-metal or soft metal products. The fastened object does not need to be tapped in advance, but only needs to process the bottom hole in advance, which greatly saves the cost and improves the efficiency.

The DIN7513 thread surface has a cutting groove that can be used as a cutting edge, so it can be self-cutting and locking like a self-tapping screw. And it has better performance than self-tapping screws. Under normal circumstances, the self-tapping screw will fail when it is folded about 8 times, while DIN7513 can be disassembled and assembled more times.

Scenario 3: When epoxy glue or viscous screw anti-loosening glue is used together, the assembly efficiency is improved and the adhesive adhesion area is increased. In the applicable scenarios with high reliability requirements such as high-speed rail and locomotives, it provides a reliable choice. Izde started supporting the first cutting thread self-tapping bolts for China's high-speed rail project many years ago, overcame the difficulties in the design and production of tooth plates, rolling teeth, etc., and successfully developed a series of products.

Eastec has always been adhering to the service tenet of "quality, lead time,cost, reputation", with smart supply chain, excellent production and processing technology and advanced testing methods,It can provide users with different standards of fasteners. We sincerely hope to cooperate with you in a friendly way and work together to overcome connection challenges together.

Customer service 1

Customer service 1  Customer service 2

Customer service 2