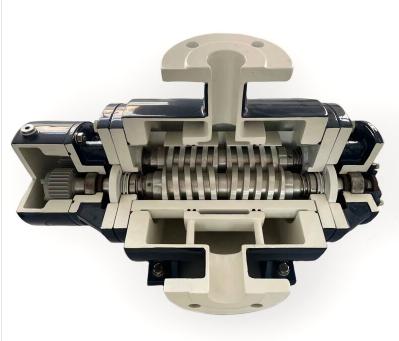

Twin-screw pump is a self-priming volumetric rotor pump, used to transport various fluid media without solid particles, widely used in petrochemical, metallurgy, electric power, shipbuilding, oil refining, machinery, papermaking, medicine, food and other fields . Its working principle is: a pair of intermeshing screws form a sealed volume cavity in the pump body bushing. When the screw rotates, the volume cavity moves axially, and the liquid in the volume cavity is continuously and smoothly transported to the outlet. , At the same time, a vacuum is formed at its inlet, and the liquid is continuously sucked in.

High efficiency: Twin screw pump adopts twin screw structure, which can achieve high efficiency fluid transportation. It is uniquely designed to provide stable flow and pressure, and can handle media with high viscosity, scale easily or containing solid particles. This makes twin-screw pumps widely used in chemical, petroleum, food and other industries.

Low energy consumption: The design of the Twin screw pump makes energy conversion more efficient and reduces the energy consumption of the pump. At the same time, due to its smooth and pulsation-free operation, it reduces the noise and vibration of the pump and improves the comfort and safety of use.

Wide speed range: Twin screw pump has a wide operating speed range and can adapt to different working conditions. Whether it is a lower speed to handle high-viscosity media or a higher speed to provide large flow rates, twin-screw pumps can work stably and reliably. Strong self-priming ability: Twin screw pump has good self-priming performance and can automatically suck in liquid from low liquid levels. This makes the installation and operation of the pump more convenient, saving the cost and space of ancillary equipment such as pump tanks.

Customer service 1

Customer service 1  Customer service 2

Customer service 2