Conductor: Bare copper multi-strand wire, compliant with DIN VDEO812

Insulation: Special polymer

Color Code: Colorful

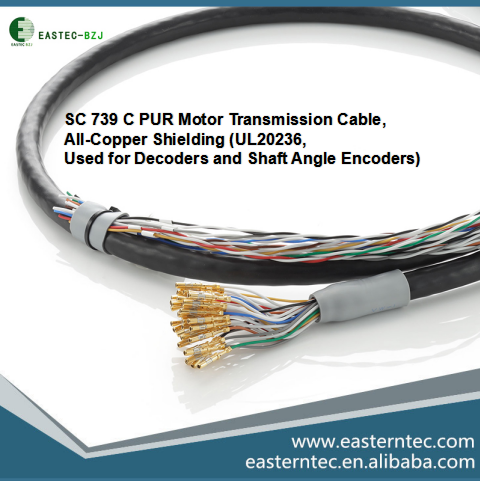

Shielding: Paired tinned copper braided sleeve

Inner Sheath: Special polymer

Conductor Structure: Single-core or paired-core wires

Conductor Structure: Twisted pair structure of single-core/paired-core wires

Armor Layer: One layer of non-woven tape or non-woven tape and PETP foil

Shielding: Tinned copper braided sleeve

Outer Sheath: Non-woven tape

Sheath Material: Rough surface PUR, TMPU compliant with DIN VDEO282+HD22.1

Sheath Color: Green (RAL6018)

Technical Parameters

Maximum Operating Voltage: Up to 30V

UL Voltage: 30V

Test Voltage U: 750V

Minimum Bending Radius

Fixed Installation: 5xD

Mobile Installation: 10XD

Continuous Movement: 12xD

Operating Temperature: UL

Fixed Installation: -40°C to +70°C, up to +80°C

Mobile Installation: -20°C to +70°C, up to +80°C

Radiation Resistance: 5x107cJ/kg

Oil Resistance: Excellent, TMPU compliant with DIN VDEO282+HD22.1

Chemical Resistance: Good resistance to acids, alkalis, solvents, hydraulic oils, etc.

Characteristics and Compliance

Characteristics: ◆Oil resistance ◆Flexible installation ◆Non-sticky installation ◆Ultra-long service life ◆Excellent electrical performance ◆Suitable for decoders and shaft angle encoders

Compliance:

Typical Applications

Used for tachometers, brakes, temperature control of motors, etc., with high flexibility and mobile connection cables. It is flexibly applied in automation technology, control and production processes, wood processing machinery, robots, and industrial factory constructions. It even meets high machinery requirements in dry, humid, and low-temperature environments.

Customer service 1

Customer service 1  Customer service 2

Customer service 2