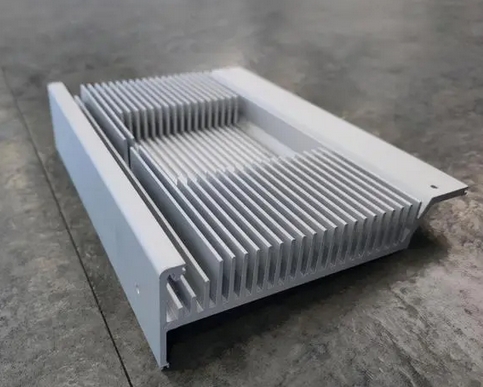

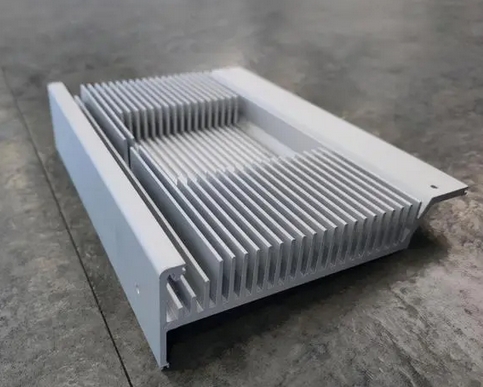

The Extrusion Technology of Aluminum Profile Radiator

Time:2023-10-20 22:23:43 Source:未知 Click:次

Introduction:

Aluminum profile radiators are widely used in the fields of power electronics and electronic equipment due to their excellent heat dissipation, lightweight, and easy processing. Extrusion technology is one of the important processes for producing aluminum profile radiators. This article will introduce the extrusion technology and its applications for aluminum profile radiators.

1. Basic Principle of Extrusion Technology:

Extrusion is a method that shapes metal by applying pressure to make it flow. In the production of aluminum profile radiators, firstly, an aluminum rod is heated to a certain temperature, and then it is extruded into the desired shape and size through an extruder. During the extrusion process, parameters such as extrusion speed and force can be controlled to adjust the quality and performance of the product.

2. Advantages of Extrusion Technology:

1. High efficiency: Extrusion technology enables continuous and automated production, greatly improving production efficiency. Compared to traditional cutting methods, extrusion technology is faster and more efficient.

2. Material-saving: Extrusion technology reduces material waste and improves material utilization. Through proper mold design, the generation of scrap can be minimized.

3. Consistent product quality: Extrusion technology ensures good consistency in shape and dimensions of products, eliminating common dimensional errors found in traditional machining methods.

4. High customizability: Extrusion technology allows for customized production based on customer requirements, meeting special demands for aluminum profile radiators in different industries.

3. Applications of Extrusion Technology:

1. Power electronics field: Aluminum profile radiators are widely used in power electronic devices such as frequency converters and inverters. Their excellent heat dissipation performance enhances the efficiency and stability of these devices.

2. Automotive industry: Electrical components in vehicles also require effective heat dissipation, and aluminum profile radiators meet this requirement, improving the performance and safety of vehicles.

3. LED lighting field: LED lighting fixtures require efficient heat dissipation systems to ensure long lifespan and stable light output, and aluminum profile radiators provide superior heat dissipation performance.

4. Communication equipment field: Power amplifiers and other components in communication equipment require efficient heat dissipation systems to ensure normal operation, and aluminum profile radiators can meet this demand.