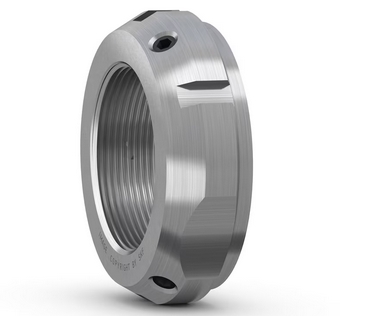

Precision Locking Nut is a high-precision and high-locking performance fastener, widely used in various machinery and equipment. Mastering the correct installation method and operating instructions for this fastener is crucial to ensure the normal operation of machinery and equipment. This article will introduce the installation guide and operating instructions of precision locking nuts in detail, helping you apply this fastener correctly.

I. Installation Guide

-

Prepare the tools and materials

Before installation, it is necessary to prepare the appropriate tools and materials. Common tools include screwdriver, wrench, and socket; while materials include lubricants. -

Select the appropriate specification

Firstly, it is essential to choose the precision locking nut with suitable specification based on the load and force of the fastened object. Generally speaking, the larger the size of the nut, the greater the load it can bear. Therefore, when the fastened object is under a larger load, it is recommended to choose a larger precision locking nut. -

Install correctly

When installing the precision locking nut, it is necessary to ensure that the threaded part of the nut is clean and free of debris to prevent it from affecting thread engagement. In addition, when using a screwdriver or other tools for installation, it is essential to make sure that the tool matches with the nut to avoid damaging the nut due to an improper tool. -

Check and maintain regularly

Long-term use of precision locking nuts may lead to wear or loosening. Therefore, regular inspection and maintenance are necessary. It is recommended to check the tightness of the nut regularly using a wrench. If loosening is found, it should be tightened promptly. In addition, for nuts that are not used for a long time, regular lubrication and maintenance should be carried out to extend their service life.

II. Operating Instructions

-

Avoid over-tightening

Although precision locking nuts have a good locking effect, over-tightening may cause the nut to break or damage the object. Therefore, it is necessary to be moderate when tightening to avoid over-tightening. -

Inspect and maintain regularly

Regular inspection and maintenance are essential to ensure the normal operation and effective performance of precision locking nuts. It is recommended to check the tightness of the nut regularly using a wrench. If any loosening is found, it should be tightened promptly. In addition, for nuts that are not used for a long time, regular lubrication and maintenance should be carried out to extend their service life.

Customer service 1

Customer service 1  Customer service 2

Customer service 2