Selection Suggestions for Welding Types

Time:2024-01-10 20:44:23 Source:未知 Click:次

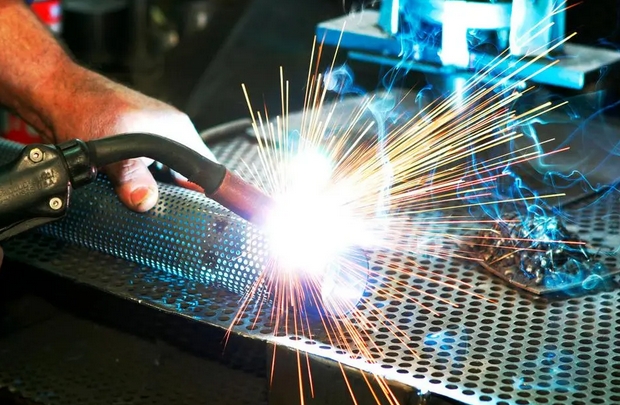

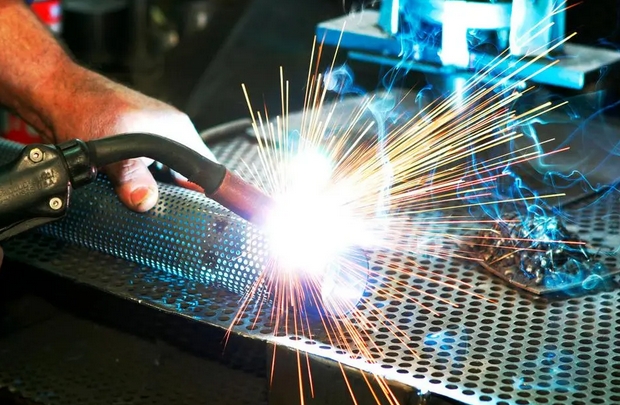

In the manufacturing and repair industries, welding is a common joining method. However, different welding methods and materials are closely related, and selecting the appropriate welding method and material is crucial to ensure welding quality. This article will explore how different welding methods affect materials and how to select suitable welding methods based on material properties.

Firstly, it is necessary to understand that different welding methods are suitable for different materials. For example, arc welding is commonly used for connecting steel, while gas shielded welding is more suitable for welding reactive metals such as aluminum and magnesium. Laser welding can be used for welding various metal and non-metallic materials. Therefore, selecting the correct welding method first requires identifying the category of the material to be welded.

Secondly, the properties of materials also affect the welding effect. For example, the thermal conductivity, melting point, and coefficient of thermal expansion of materials will all affect the temperature distribution and stress state during the welding process, thereby affecting the quality of the weld. Generally speaking, materials with high thermal conductivity are more suitable for fast welding because they can transfer heat faster; materials with high melting points require higher welding temperatures; materials with large coefficients of thermal expansion may produce larger internal stresses during welding, leading to cracks in the weld.

In addition, the chemical composition of materials can also affect the welding effect. For example, certain alloy elements may increase the material's susceptibility to oxidation, making the welding process more likely to produce oxides and pores, thus reducing the quality of the weld. Therefore, for materials containing specific alloy elements, special welding measures may be required, such as using inert gas shielded welding.

When selecting a welding method, it is also necessary to consider the design requirements of the welded structure. For example, for structures that require high-strength connections, friction stir welding or electron beam welding may be needed, which can produce high-strength welds; for structures that only need sealing connections, soft soldering or laser welding may be chosen, which can produce smooth welds.

Finally, the economic aspect of welding needs to be considered. Different welding methods have different equipment costs, energy consumption, and maintenance costs. Therefore, when choosing a welding method, these factors should also be taken into account.

In summary, the selection of welding methods and materials is a complex process that requires considering multiple factors. Only by fully understanding these factors and making reasonable choices can the quality of welding be guaranteed and meet the performance requirements and service conditions of products.

In future work, we will continue to study the issues of welding technology and material selection in depth, aiming to provide more references and guidance for the manufacturing industry. At the same time, we welcome valuable opinions and suggestions from readers to jointly promote the development of welding technology.