Analysis of the Stainless Steel Etching Process

Time:2024-03-25 15:21:36 Source:未知 Click:次

Abstract: This article provides a detailed introduction to the manufacturing process, techniques, and precautions of the stainless steel etching process. By understanding the principle of etching technology and mastering the manufacturing process and techniques, production efficiency and product quality can be improved, and the generation of defective products can be reduced. Meanwhile, adhering to the precautions ensures production safety and environmental protection.

I. Introduction

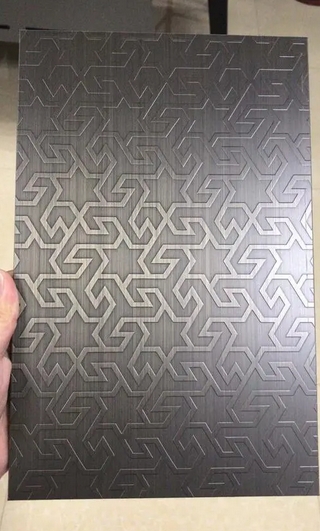

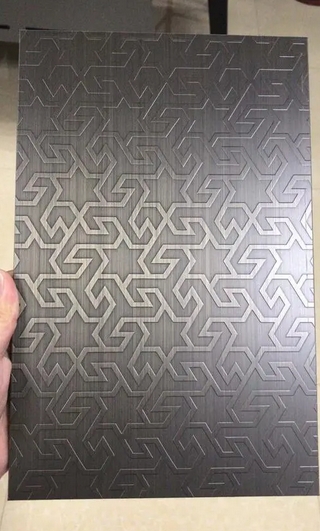

Stainless steel etching technology is a process that chemically or physically forms concave and convex patterns on the surface of stainless steel, which is widely used in electronics, electrical appliances, medical devices, and other fields. Etching technology not only enhances the aesthetics of products but also increases their functionality. This article will provide a comprehensive introduction to the manufacturing process, techniques, and precautions of the stainless steel etching process.

II. Manufacturing Process

1. Design Drawing: According to product requirements, design the corresponding drawings using professional software such as CorelDRAW, Photoshop, etc. When designing, pay attention to the thickness of lines and spacing, as well as whether they meet production requirements.

2. Plate Making: Produce the drawings into plates through photolithography technology. Common plate materials include transparent胶版, acetate版, etc. Pay attention to the cleanliness of the plate and the clarity of the patterns during plate making.

3. Hanging Plate: Install the prepared plate materials into the etching machine and adjust the position.

4. Etching: Turn on the etching machine and immerse the stainless steel plate into the etching solution. Through the chemical reaction of the etching solution, the unwanted parts on the surface of the stainless steel are corroded away. During the etching process, control parameters such as etching speed, temperature, and pressure to ensure the accuracy and uniformity of the patterns.

5. Post-processing: Remove the etched stainless steel plate from the etching solution and perform cleaning, de-greasing, and drying processes. Pay attention to cleaning and rust prevention during post-processing.

6. Inspection: Quality inspect the produced products after etching to check if the patterns meet the design requirements and if there are any scratches, bubbles, or other irregularities.

III. Techniques and Precautions

1. When designing drawings, fully consider the limitations of production technology, and rationally design the line thickness and spacing of the patterns. Too thin lines or too small spacing will increase the difficulty of etching and may even be impossible to complete.

2. During plate making, pay attention to the cleanliness of the plate and the clarity of the patterns. Plate contamination or unclear patterns will result in poor etching effects.

3. During the etching process, adjust the etching parameters according to the material and thickness of the stainless steel. Different materials and thicknesses of stainless steel will have different etching speeds, temperatures, and pressure requirements.

4. During the etching process, constantly monitor the concentration, temperature, and cleanliness of the etching solution. Low solution concentration, high temperature, or poor cleanliness will result in poor etching effects.

5. After post-processing, fully clean and apply rust prevention treatment to ensure the surface finish and rust prevention performance of the product.

6. Adhere to production safety regulations to ensure personal safety and environmental protection during production.

IV. Conclusion

Stainless steel etching technology is a complex and delicate process. Mastering the manufacturing process and techniques can improve production efficiency and product quality. Meanwhile, adhering to precautions ensures production safety and environmental protection. Only by continuously summarizing experience and optimizing production processes can better development be achieved in the field of stainless steel etching.

Customer service 1

Customer service 1  Customer service 2

Customer service 2