The Manufacturing Process of Water Cooling Systems

Time:2024-05-14 16:20:40 Source:未知 Click:次

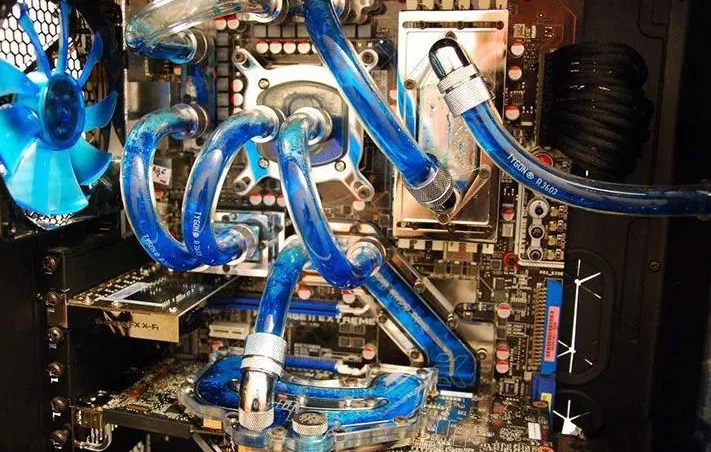

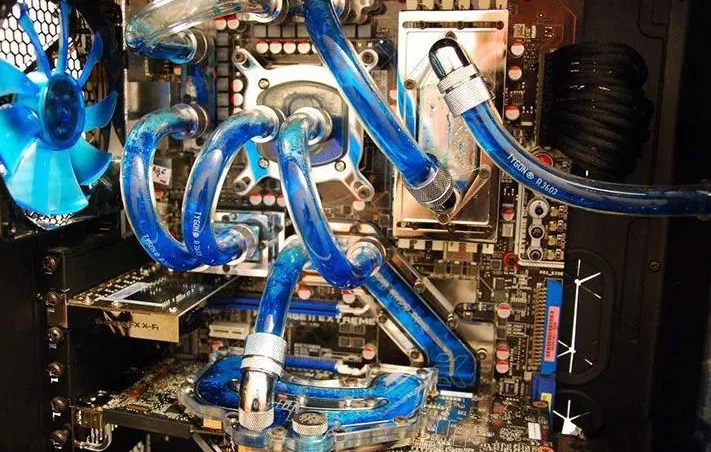

Introduction: As computer hardware performance continues to improve, the demand for efficient cooling systems has become increasingly stringent. Water cooling systems, with their superior cooling performance and lower noise levels, have gained popularity among many high-end hardware enthusiasts. This article will provide a detailed introduction to the manufacturing process of water cooling systems, helping you better understand how these cooling units are produced.

1. Mold Design and Manufacturing: The design of water cooling systems must consider factors such as cooling efficiency, structural strength, and weight. After the design is completed, corresponding molds need to be manufactured for mass production.

2. Material Selection: Water cooling systems commonly use metals such as aluminum, copper, and stainless steel, which have good thermal conductivity and corrosion resistance.

3. Processing: According to the molds, the metal materials are processed through stamping, welding, polishing, and other techniques to form the main structure of the radiator.

4. Heat Sink Processing: The heat sink is a key part of the water cooling system, and its processing technology directly affects the cooling performance. Heat sinks are usually made of aluminum, processed through stamping, cutting, and then polished and anodized to improve the surface finish and corrosion resistance.

5. Water Pump Installation: The water pump is the power source of the water cooling system and needs to be installed in the radiator body and connected to the water pipes.

6. Assembly: The heat sink, water pump, pipes, and other components are assembled into a complete water cooling system. During assembly, it is essential to ensure that all parts are securely connected to avoid leaks or looseness.

7. Performance Testing: After assembly, the water cooling system undergoes performance testing to check its cooling efficiency, noise level, and other standards.

8. Packaging: After passing the test, the water cooling system is cleaned, dried, and packaged for shipping.

Three Trends in Water Cooling System Manufacturing:

1. Material Innovation: With the research and application of new materials, future water cooling systems may adopt lighter, stronger, and better thermally conductive materials.

2. Design Innovation: By improving the design of the radiator, the efficiency of heat dissipation can be increased, and the noise level can be reduced.

3. Intelligence: Future water cooling systems may integrate more intelligent features, such as temperature control and automatic regulation of water flow, to meet the needs of different users.

Conclusion: Water cooling systems, as an efficient cooling solution, are significantly influenced by their manufacturing process on cooling performance and user experience. With continuous technological innovation and material research, the performance and reliability of water cooling systems will be further improved, providing superior cooling services for computer hardware. It is hoped that this article will provide you with a beneficial understanding of the manufacturing process of water cooling systems.