Choosing Water Cooling Radiator Processing Equipment

Time:2024-05-16 16:19:38 Source:未知 Click:次

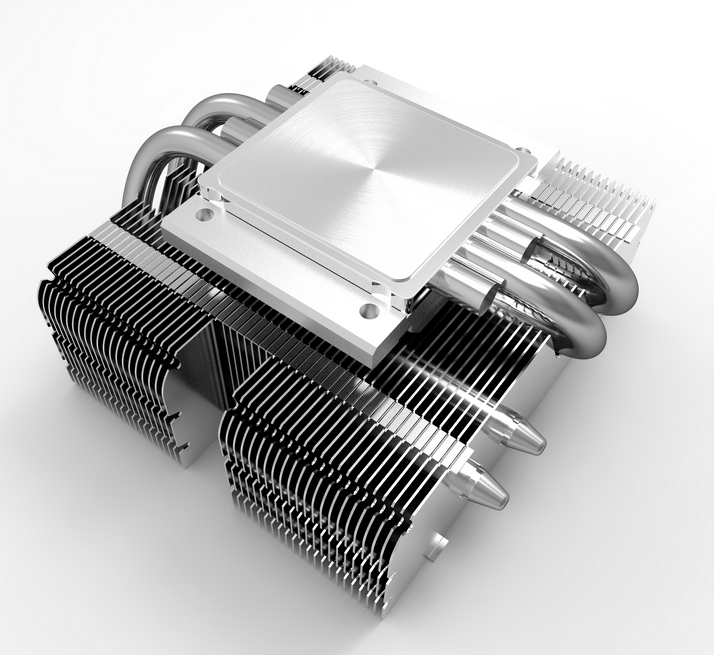

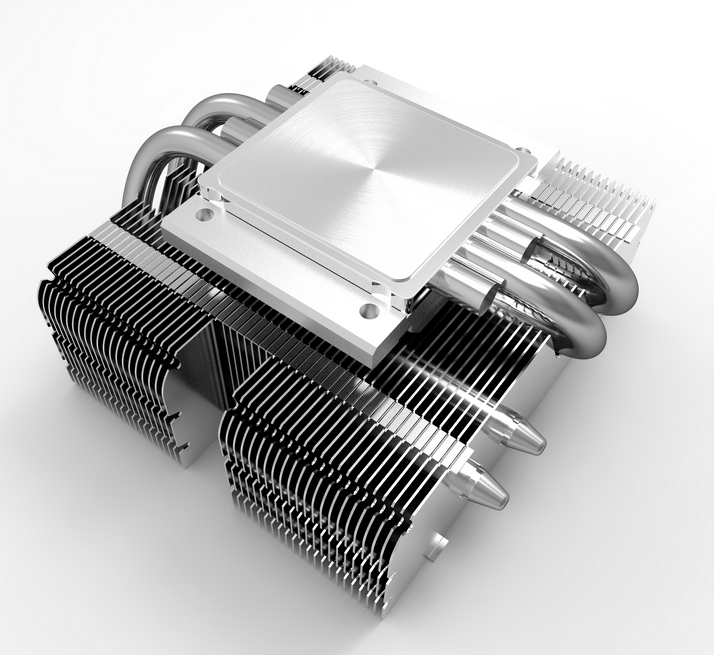

With the rapid advancement of technology, the demand for cooling radiators has increased dramatically, especially in high-performance computers, servers, and new energy vehicles. Under these circumstances, selecting the appropriate water cooling radiator processing equipment to improve production efficiency and product consistency has become a focus for enterprises.

I. Principles for Choosing Water Cooling Radiator Processing Equipment

1. Equipment Performance: The performance of the equipment, including processing accuracy, speed, and stability, should be the first consideration. High-performance equipment can enhance production efficiency and ensure product consistency.

2. Equipment Compatibility: During the processing of water cooling radiators, various materials such as aluminum, copper, and stainless steel may be involved. Therefore, the equipment should be capable of adapting to different materials and meeting the production needs for each.

3. Degree of Equipment Automation: High levels of equipment automation can reduce manual intervention, lower production costs, and improve production efficiency. Additionally, automated equipment is easier to implement real-time monitoring of the production process, ensuring product quality.

4. Equipment Maintenance and Repair: Equipment maintenance and repair are crucial for smooth production. Choosing equipment that is easy to maintain and has a low failure rate can reduce production risks.

5. Strength of Equipment Suppliers: Choosing equipment suppliers with strong research and development capabilities and comprehensive after-sales service systems can provide strong support for the enterprise's production.

II. Measures to Improve Production Efficiency

1. Optimize Production Processes: By optimizing production processes, unnecessary steps can be eliminated, increasing production speed.

2. Adopt High-speed Machining Technology: High-speed machining technology can complete complex processing tasks in a short time, improving production efficiency.

3. Use Cluster Machining: Cluster machining allows for the coordination of multiple machines to perform multiple tasks simultaneously, enhancing production efficiency.

4. Improve Employee Skills: Training employees to improve their operational skills and professional knowledge can increase production efficiency.

III. Measures to Ensure Product Consistency

1. Strictly Control Raw Material Quality: The quality of raw materials directly affects the quality of the final product, so strict screening and testing of raw materials is necessary.

2. Use Precision Processing Equipment: Precision processing equipment can ensure the consistency of product dimensions, surface quality, and other indicators.

3. Optimize Processing Technologies: By optimizing processing technologies, various errors during processing can be reduced, ensuring product consistency.

4. Implement Total Quality Management: Total quality management includes quality control during production and finished product quality testing, which can effectively reduce the rate of defective products.

In conclusion, the selection of water cooling radiator processing equipment is crucial for improving production efficiency and product consistency. Enterprises should choose appropriate equipment based on their needs and take corresponding measures to ensure smooth production and meet market demands. Additionally, enterprises should also pay attention to industry development trends, continuously introduce new technologies and equipment, and enhance their competitiveness.

Customer service 1

Customer service 1  Customer service 2

Customer service 2