Metric Grease Fittings Design Considerations

Time:2024-08-21 16:11:28 Source:未知 Click:次

When it comes to metric

grease fittings (sometimes referred to as European grease fittings), one of the biggest considerations is how they are made and how they are different from SAE grease fittings. Will they fit your

grease fitting tools? Will the threads align with the mating component? Will the shapes be different and does that matter?

Here, we discuss metric grease fitting design characteristics, how they differ from SAE grease fittings, and whether or not they have a functional impact on your application.

Metric Grease Fitting Design vs. SAE Grease Fittings

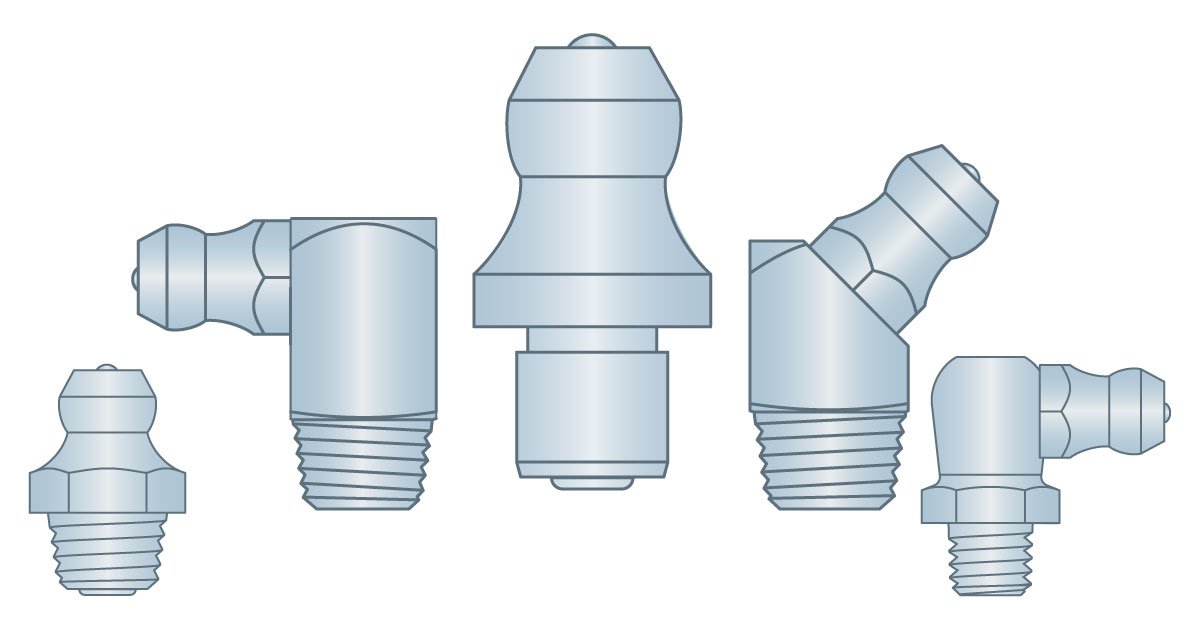

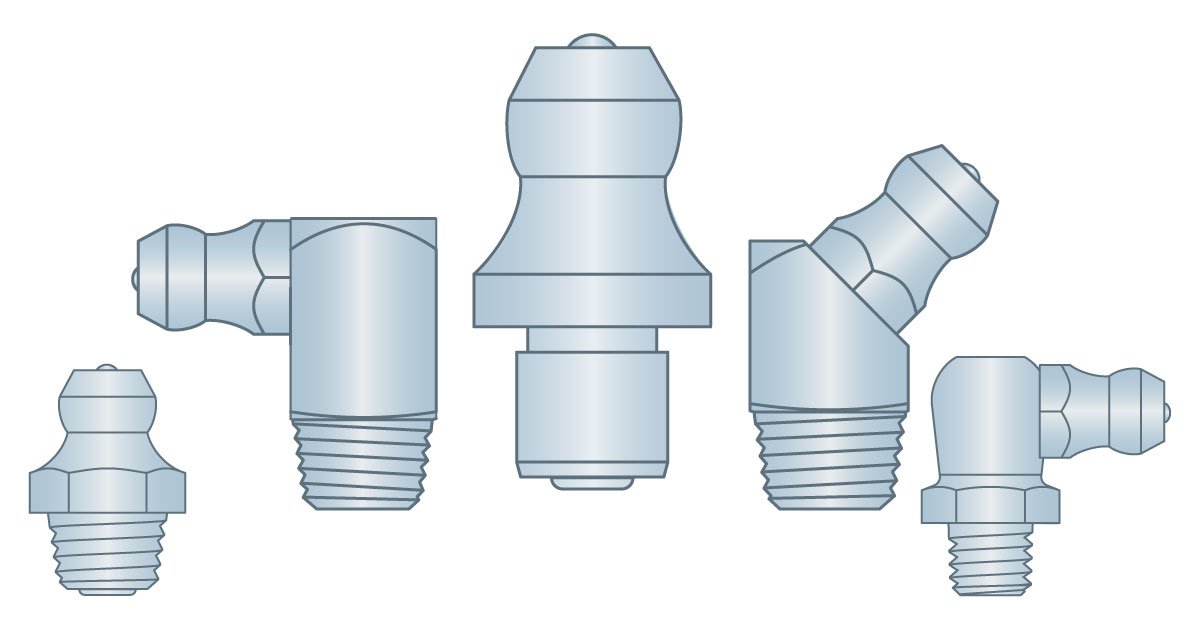

Metric grease fittings share a similar aesthetic design to SAE fittings, other than the shank threads and a few body shapes that are specific to metric standards. The characteristics that are specific to metric grease zerk fittings revolve around the techniques used to manufacture and machine the fittings.

Metric grease zerks are most commonly governed by DIN (

Deutsches Institute for Normung - or

German National Standards Institute ) Standards, while SAE zerks are - unsurprisingly - governed by SAE International Standards (

Society of Automotive Engineers ). We explain these organizations in more detail in our

Fastener Standards guide. These standards - which cover a wide variety of fasteners - dictate the design differences you will notice in your grease zerk fittings.

Design differences include the nipple profile, the head’s ability to align with the coupler, body type, thread specifications, and manufacturing standards.

When you need large custom orders, Huyett now completes that order with better precision in less time. It also means we have more resources to dedicate to your small custom batches. This new addition will facilitate a more streamlined machining process that will help us deliver runs of any size with shorter lead times, more accuracy, and better quoting mechanisms to you, our customer.

The Tsugami B0325-iii introduces three core improvements to our lathe production processes, which in turn offer you three key benefits to pass on to your customers.

Nipple Variations

DIN Standard head profiles are similar to SAE Standard profiles, except that DIN heads are machined from a sphere. However, standard couplers will lubricate both fitting styles.

Coupler Alignment

Nipples or heads are hardened to provide additional strength and to minimize wear from repeated contact with the jaws of a grease gun coupler during use.

Contour of the tip must allow the coupler to seal within 50 degrees misalignment with the axis of fitting.

Body Types

Body types are specified by DIN 71412. Square and hex bodies are allowed on angled fittings, and these unique body forms may help users identify metric fittings. Standard, round body forms most common in the U.S. are often substituted with no impact on functionality.

While cosmetically different, DIN body types perform the same as SAE fittings.

Thread Specifications

-

Metric Tapered Threads: ISO metric threads are the most widely used threads in the world. They share the 60° thread profile of NPT, but the shanks are metric sized. Metric threads are tapered unless otherwise noted.

-

Whitworth Threads: The less common Whitworth form British thread is often considered to be metric. This is likely due to their non domestic origin.

Tapered fittings are designed to mate in parallel threaded holes. Thread sealant is required for a leak-free seal.

Metric Grease Fittings Manufacturing

Metric zerks that comply with DIN standard specifications are manufactured to very high standards and undergo strict inspection to ensure conformity.

Production

-

Turned & Formed: Fittings are turned and threads are formed by rolling.

-

Heat Treated: The nipple is hardened. Please note: Threads are also hardened on thread forming fittings.

-

Plated: Zinc yellow plating is typically specified because of its added corrosion resistance as compared to zinc clear plating.

-

Assembled: Ball check and spring along with any other critical pieces are inserted and the lip is rolled to secure internal parts.

-

Optical Inspection: Inspection ensures that no part leaves the facility without a ball check.

Metric Grease Fittings Functionality vs. SAE Grease Fittings

The main functional difference between metric zerks and SAE zerks is in the shank. Whether it is threaded or drive-style, the two types of zerks are not readily interchangeable.

Threaded Grease Fittings

Threaded metric zerks must match with metric threads in the mating component - the opposite is true for threaded SAE zerks and their mating component. When it comes to

installing grease fittings, 4-way

grease fitting multi-tools will install and remove both types of grease zerks. However, they will only re-tap SAE threads - not metric threads - in the mating component.

To switch between the two types of zerks, you would need to clean and re-tap the mating hole to fit the appropriate thread standard and size (you can learn more about the different types of zerk threads you will run across in our

Grease Fitting Threads guide). This would require a tap and die set. Depending on your application, it may be more worthwhile to ensure you have enough of the correct fitting on-hand instead.

Drive-Type Grease Fittings

While SAE drive-type zerks are serrated so the shank catches on the mating component, metric drive-type zerks feature a smooth shank. Both types of zerks require a smooth mating hole for installation.

Drive fitting tools will install both standards; however, the multi-tools will

not install metric zerks - it will only

remove broken ones.

If you want to switch from metric zerks to SAE zerks, this should not be a problem. However, if you want to switch from SAE to metric, you will need to smooth down the hole, as the serrated SAE edges will have made it rough. You may also need to consider the zerk size, since cleaning the hole may have widened it.

These are clear-cut differences most of the time. However, confusion arises if a grease zerk features hybrid characteristics (Huyett does not offer these). For example, some zerks might have DIN threads with SAE compliant nipple profiles, plating, and/or heat treatment. This causes problems when trying to match tools and grease guns to the zerk in question or if a design requires specific standard compliance. Such a design is rare, but it is important to note that they exist so as not to be caught off guard.

The Bottom Line

Metric grease fittings feature aesthetic characteristics that are similar to SAE-compliant grease fittings, making them easy to use with standard grease guns, grease couplers, and accessories. The main difference between SAE and metric grease fittings to consider is their threads or shank design - be prepared to clean or re-tap holes if you plan on interchanging one style for the other.

Huyett is a distributor of grease fittings, including standard zerks, safety vent fittings, flush fittings, button head grease fittings, and more. We also offer grease guns, tools, couplers, and accessories like grease fitting caps, grease fitting adapters, grease gun hoses, and header blocks to help you with all your grease fitting application needs. Visit our

Grease Fitting FAQ page, our

Grease Fitting Catalog, or

contact our Sales Team for more information.

Customer service 1

Customer service 1  Customer service 2

Customer service 2