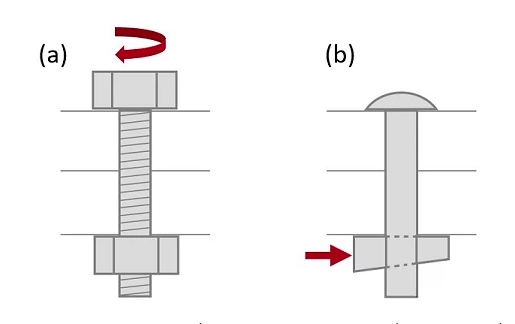

Torque is the force that causes an object to rotate, while tension is the force that stretches or elongates an object. How are bolt torque and tension related? Torque is a method of generating tension by stretching a bolt. To intuitively show the rotational force that leads to bolt tension, consider the threads of a bolt as wedges or coils wrapped around the bolt body. When torque is applied to the bolt and it rotates relative to the nut or thread hole, the wedging action between the threads stretches the bolt, compressing the clamping components. This wedging action is similar to the principle of one of the earliest fastener forms, the friction bolt of the Roman Empire period. As shown in Figure 1b, a pin or wedge hammer is driven into the slot at one end of this old bolt to produce tension.

Torque is the most commonly used method in industrial and home settings to generate bolt tension and the corresponding clamping load in joints. In most applications, this is a highly practical and cost-effective method for assembling bolt joints. Manual wrenches and manual torque wrenches are primarily used for smaller bolt diameters (≤1 in. [≤25 mm]), while impact wrenches and hydraulic torque wrenches are preferred for bolts with diameters larger than 1 in. (25 mm). Is torque accurate in producing bolt tension?

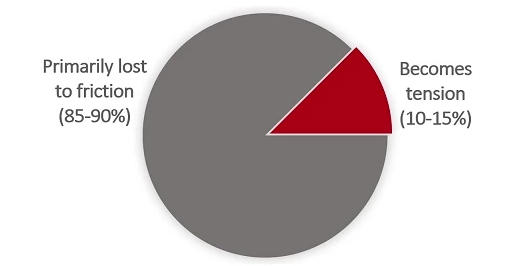

To properly answer this question, first consider that only about 10-15% of the input torque actually stretches the bolt; the remaining 85-90% of the input torque is mainly used to overcome friction between the matching threads and friction under the bolt head or nut. Friction depends on many variables, including but not limited to lubricant type and conditions, surface roughness, coatings, and materials, so friction can vary significantly even between bolts in the same component. Moreover, since friction force dominates the torque-tension relationship, even a small change in friction force can lead to a significant change in bolt tension.

Therefore, it is not surprising that torque, the most common method of producing tension in bolts, is also the least accurate. The widely accepted consensus is that the variation in bolt tension due to torque control is ±25% to ±35%. A variation of up to ±35% means that under the exact same measured torque, one bolt's tension may be less than half the tension of another bolt. After considering any tolerances in the torque values, the variation may be even greater. Thus, bolt joints tightened with precise torquing are not necessarily bolt joints with precise tensioning.

Alternative methods for producing bolt tension

In critical bolt connections, torque control alone is often not precise enough to provide a safe and effective bolt connection, and other methods of creating bolt tension are usually more appropriate or require supplemental methods to validate bolt tension. Moreover, as bolt diameter increases, torque becomes physically impractical or too time-consuming, necessitating the use of alternative methods.

Hydraulic tensioning, whether in the form of bolt tensioners or hydraulic nuts, uses hydraulic power to stretch threaded fasteners. Since hydraulic pressure can be easily and accurately measured, and the pressure area of the hydraulic cylinder remains constant, hydraulic tensioning is more precise than torque control methods (bolt tension variation < ±10%). In both hydraulic tensioning methods, it is important to note that there is no high torque rotational force and its related friction. The absence of sliding surfaces in contact under high load reduces the risk of thread wear, which is another advantage of hydraulic tensioning.

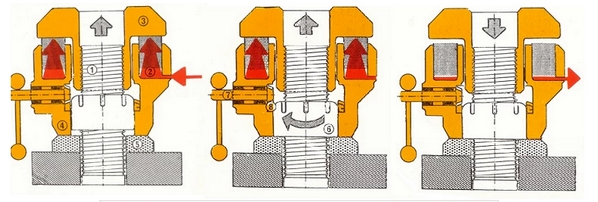

A bolt tensioner is a tool that grips and pulls the threads extending outside the nut, as shown in Figures 3 and 4. The hydraulic nut uses the same principle, that is, hydraulic tensioning of the bolt, but its function is not just tightening. By replacing the standard nuts used in the application with a hydraulic nut, the nut becomes part of the structural bolt joint. After reaching the appropriate pressure, the locking ring of the hydraulic nut holds the tension of the bolt in place mechanically.

A significant feature of the hydraulic nut is that it can tension all bolts in a joint simultaneously. By eliminating the need for tightening or sequence modes, assembly and disassembly time can be shortened. Additionally, the interaction or load sharing between adjacent bolts is minimized, making the tension more uniform among bolts.

Bolt heating is another method of generating bolt tension, but it is usually only used for very large bolt diameter applications. In this time-consuming method, bolts or columns are stretched with heat, while simple manual tools are used to rotate and tighten the nuts. The tension of the bolt or double-ended bolt must be measured directly, but only after the bolt or double-footer has cooled. The process of heating,

Customer service 1

Customer service 1  Customer service 2

Customer service 2