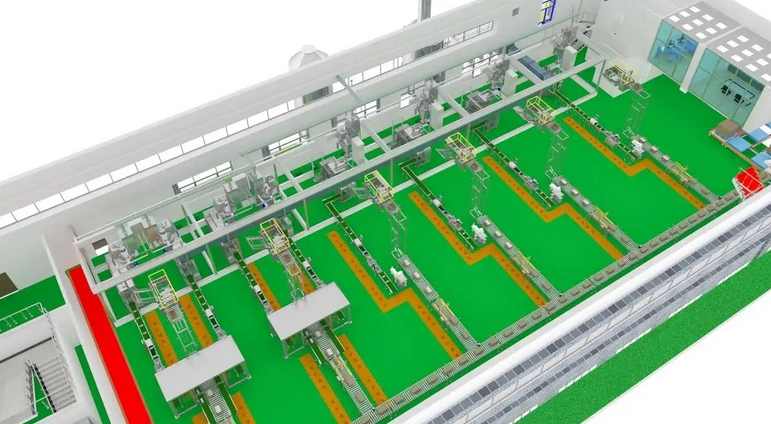

The content of workshop layout design is divided into factory layout and equipment layout. Factory layout considers the division of production areas, organization of production lines, and composition of factory area, while equipment layout focuses on the positioning of equipment, process pipelines, and maintenance equipment. When designing, factors such as production, equipment maintenance, space utilization, safety and hygiene, and transportation distances must be considered.

Common methods of workshop layout include the straight-line layout, process layout, fixed layout, and mixed layout. The straight-line layout is suitable for mass production with high efficiency but is less adaptable to multi-product production. The process layout is suitable for small batch and multi-product production, facilitating centralized management. The fixed layout is used for large, immobile products, such as aircraft assembly. The mixed layout combines various methods to complement different functions.

In summary, workshop layout is a complex process that requires a comprehensive consideration of various factors to ensure production efficiency and safety and hygiene, while also allowing for future development space.

Customer service 1

Customer service 1  Customer service 2

Customer service 2