Silk screen printing is a printing technology that uses a screen mesh tensioned on a frame to create the printing plate, characterized by simple equipment, convenient operation, and low cost, widely used in various printing products. Pad printing is suitable for surface printing of electronic products, using a cliché and silicone rubber pad to transfer images and text. Curve printing involves transferring ink to a curved surface and then transferring it to the surface of the finished product. Etching printing process prints embossed ink on smooth substrates to create a metal etching effect. Lithography transfers the image ink to the substrate using the oil-water separation principle.

Hot stamping is a process that stamps colored foil with text and patterns on book covers, etc. Electropolishing aluminum hot stamping uses the principle of heat transfer to transfer the aluminum layer to the surface of the substrate. Water transfer printing technology uses water pressure to transfer patterns to the surface of objects. IMD is an in-mold decoration technology, divided into types such as IMR and IML. Mechanical polishing, electrolytic polishing, and chemical polishing are common surface treatment methods that achieve a smooth effect through cutting, electrolysis, and chemical dissolution, respectively.

Etching technology removes material through chemical reactions or physical impacts, divided into wet etching and dry etching. 3D diamond cutting uses diamond tools to process on metal surfaces. High-gloss oxidation achieves a high-gloss effect through anodizing. Electrophoretic coating technology uses an electric field to deposit paint particles on the surface of the workpiece. Powder coating uses high-voltage electrodes to charge powder particles and adsorb them onto the surface of the workpiece.

Optical coating technology involves depositing a metal or dielectric film on the surface of optical parts. Nano-imprint technology has the advantages of ultra-high resolution and low cost. Hot gold stamping technology transfers the aluminum layer in electroplated aluminum to the surface of the substrate. Embossing process forms concave-convex patterns during the rolling of metal plates. VCM film-laminated board process and PCM pre-coated board process are technologies for bonding PVC film and pre-coating metal surfaces, respectively.

Surface hardening technology increases the hardness of the part's surface layer. Galvanizing involves zinc coating on metal surfaces for corrosion protection. Powder spraying uses electrostatic force to make powder coatings adhere to the surface of the workpiece. Microarc oxidation generates a ceramic film layer on the surface of aluminum, magnesium, and titanium alloys. Metal wire drawing creates lines through the use of sandpaper. Fire blue involves filling the body with colored glaze and firing it. Sandblasting creates a matte surface that diffuses light.

Heat transfer printing is an emerging printing technology, divided into transfer film printing and transfer processing. Laser engraving uses lasers to carve marks on the surface of materials. PVD is physical vapor deposition, depositing a film on the workpiece. Electroplating involves depositing another metal on a metal surface using the principle of electrolysis. Vacuum evaporation is the process of evaporating coating materials under vacuum conditions. Electroplating technology uses the principle of electrolysis to deposit metal on the surface of the base material.

Nano spray plating technology achieves a colorful mirror-high gloss effect through spraying.

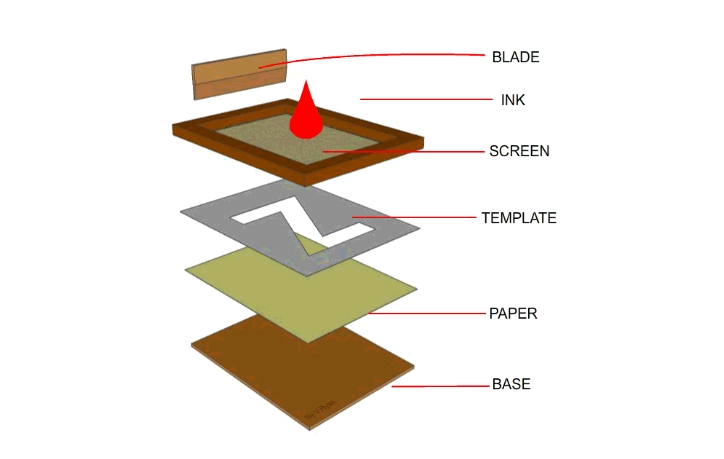

Calendering is a finishing process that enhances the gloss of fabrics. Flat screen printing is suitable for small batch and multi-variety production. Spray painting technology uses a spray gun to evenly apply paint to the surface of the workpiece. PET film UV transfer printing uses UV transfer adhesive to achieve special effects. Film forming is the process of heating and softening the film, then shaping and cooling it. Potting process involves mixing two types of glue to coat the product surface. Laser bite flower uses high-energy density lasers to react with the steel surface to create decorative patterns. Sandblasting changes the surface morphology of the workpiece using high-speed jet beams. Anodizing technology combines sandblasting and anodizing processes to improve the corrosion resistance and appearance of the workpiece.

Customer service 1

Customer service 1  Customer service 2

Customer service 2