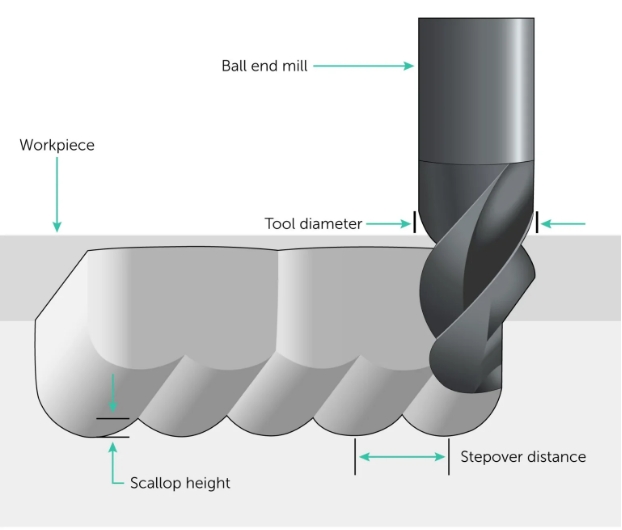

In CNC milling operations, the term “stepover” refers to the lateral distance between consecutive tool paths of a cutting implement. Typically, the recommended stepover distance is a percentage of the cutter’s diameter. A machinist can enter the calculated stepover dimension in computer-aided manufacturing (CAM) software or use a CNC stepover calculator in CAM. While an experienced machinist may be able to specify a CNC stepover based on previous projects, there is a simple stepover calculation to use with CNC milled parts.

Calculating Stepover CNC Stepovers are typically given as a percentage of the tool diameter using the following formula.

Stepover = Tool Diameter x CNC Stepover Percentage

Follow these steps to calculate CNC stepover using some sample data.

- 1. Determine the cutting tool diameter.

In this example, we’ll use a 10 mm end mill.

- 1. Set the stepover percentage.

For roughing, a common range is 40% to 60% of the tool diameter. We’ll use 50%. For finishing, the range is usually 5% to 20% instead. We’ll use 10%. 3. Calculate the stepover distance.

Roughing pass with a 10 mm tool at 50% stepover: Stepover = 10mm x 0.50 = 5mm

Finishing pass with a 10mm tool at 10% stepover: Stepover = 10mm x 0.10 = 1mm

Customer service 1

Customer service 1  Customer service 2

Customer service 2