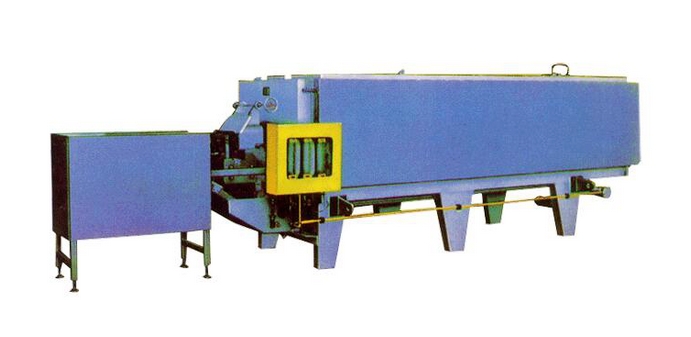

Mesh belt furnace, suitable for batch medium and small mechanical parts such as standard parts, bearings, chains, self-tapping screws, textile hardware, hand tools, spring washers, various types of textile needles, sewing needles for carburizing, carbonitriding, quenching and other heat treatments in a controlled atmosphere. This issue introduces the principle, structure, and common problem analysis of the mesh belt furnace, let's take a look!

Mesh Belt Furnace Working Principle

The mesh belt furnace uses an intermittent advancing belt to convey the workpieces through a temperature-controlled heating zone, then drops them into the quenching oil tank, and is automatically removed by a hoist—a continuous heat treatment furnace. It can perform quenching, thin-layer carburizing, carbonitriding, and other heat treatment processes under a controlled atmosphere. During the heat treatment process, there is no collision between the workpieces, and they are evenly heated through the furnace chamber. With the effect of the controlled atmosphere, air is prevented from entering the furnace. As a result, the surface of the treated workpieces is smooth, without decarburization, uniformly surfaced, with minimal deformation, and of high quality.

Structure of the Mesh Belt Furnace

The furnace body framework consists of a box body and a support frame, both made of high-quality shaped steel and steel plate welding. For the convenience of the operator's maintenance or cleaning of the furnace chamber, the furnace chamber is designed as an upper and lower split structure, allowing the removal of the upper furnace cover.

The hearth of the mesh belt quenching furnace adopts a full fiber composite structure with excellent thermal insulation properties. Silicon aluminum fiber felt is used on both sides and the top of the furnace chamber, which can be disassembled and installed with the furnace cover as a whole, offering excellent thermal insulation properties and saving more than 40% energy compared to brick-lining furnace linings.

Mesh Belt Quenching Furnace Heating Elements: The heating elements are made of high-quality resistance wire wound horizontally and inserted from one side of the furnace body into the furnace chamber, arranged on the upper and lower sides of the furnace tube. This type of heating element is reliable in use and convenient for maintenance and can be replaced without stopping the furnace when needed.

Common Faults and Solutions for Mesh Belt Quenching Furnace

Q: What to do if the mesh belt of the mesh belt quenching furnace breaks inside the furnace?

A: Pull out the entire mesh belt, open the cover plate at the back of the return channel, first pass a piece of wire through the furnace casing and then through the return channel to underneath the loading table, lay one end of the mesh belt flat on the loading table and secure it tightly with the wire. Two people can pull it to the plane of the loading table and connect it with a wire thread.

Q: How to set the temperature for a five-zone mesh belt quenching furnace?

A: For a five-zone mesh belt quenching furnace, when setting the temperature, the temperature of the two zones at the inlet and outlet ends can be slightly higher than the working temperature, and the middle three zones can be set to the working temperature. Typically, the temperature of the first zone is set at 780 degrees Celsius, and the quenching temperature for the second to fifth zones is set at 840 degrees Celsius.

Q: Can the mesh belt quenching furnace quench steel files?

A: Yes, it should be able to, as long as you choose a power size that meets the processing requirements. I learned before from Gaoshi Electromagnetic that the larger the power, the larger the workpiece that can be processed, and the smaller the power, the smaller the workpiece that can be processed.

Q: How to solve the water leakage that occurs during high-temperature sintering in the powder metallurgy mesh belt sintering furnace?

A: If water leakage is found in the cooling section, it should be replaced or repaired. However, when the furnace is started, there may be a water leakage phenomenon that disappears after about half an hour, which is fine. If it continues to leak, stop the furnace and replace the furnace core tube.

Customer service 1

Customer service 1  Customer service 2

Customer service 2