Bolt connections are widely used in various fields such as automobiles, chemical industry, large presses, ships, and aviation. The axial preload of bolts has a significant impact on their service life and connection conditions. This study aims to establish the relationship between the axial force of bolts and the energy of ultrasonic surface waves, fit the nonlinear curve, and validate it through experiments. Additionally, the study combines the surface wave energy dissipation method to monitor the attenuation of bolt axial force online, providing a new method for detecting the attenuation of bolt axial force, thereby achieving accurate and rapid monitoring of bolt axial force.

Detection Principle

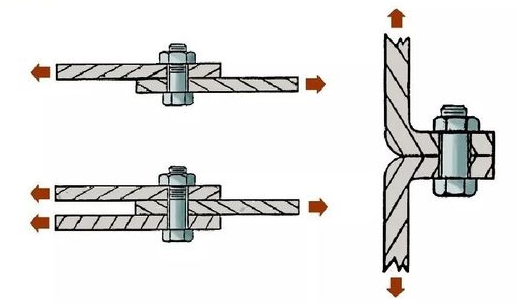

Bolt connections are formed by applying axial preload to two or more connecting parts through bolts and nuts. The magnitude of the preload determines the tightness of the connection, and bolt connections play an important role in many areas of mechanical manufacturing. The surfaces of the connecting parts are irregularly distributed with many micro-convexities and pits. When preload is applied to the bolt, the micro-convexities in contact between the upper and lower connecting parts will squeeze each other, causing a certain degree of elastic-plastic deformation of the micro-convexities at the interface under external force, thereby increasing the real contact area between the micro-convexities, and consequently, the real contact area between the connecting plates also continuously increases.

Literature [13] analyzed through Hertz contact theory that within a certain preload range, the real contact area at the interface increases with the increase of axial preload. Ultrasonic waves propagate through the contact points of micro-convexities at the interface, so the actual contact area between the two connecting parts is directly proportional to the energy of the ultrasonic transmission signal. However, when the preload increases to a certain extent, the micro-convexities between the connecting parts are basically flattened, the contact area at the interface reaches its maximum, and the energy of the ultrasonic transmission signal gradually approaches saturation and no longer changes.

Experimental Design and Method

To verify the relationship between the axial force of bolts and the energy of ultrasonic surface waves, an experimental setup was designed. The experimental setup includes bolt connecting parts, ultrasonic transmitting and receiving devices, force sensors, and a data acquisition system. First, different axial preloads are applied to the bolt through the force sensor, and the energy of the ultrasonic transmission signal under each preload is recorded. Then, the data acquisition system is used to collect and process the ultrasonic signals to obtain the energy values of the ultrasonic transmission signals.

Experimental Results and Analysis

The experimental results show that within a certain preload range, the energy of the ultrasonic transmission signal increases with the increase of axial preload, showing a significant positive correlation. When the preload reaches a certain value, the energy of the ultrasonic transmission signal tends to saturate and no longer changes significantly with the increase of preload. This result is consistent with theoretical analysis, verifying the nonlinear relationship between the axial force of bolts and the energy of ultrasonic surface waves.

Online Monitoring by Surface Wave Energy Dissipation Method

Based on the above experimental results, an online monitoring method for bolt axial force based on the surface wave energy dissipation method is proposed. This method monitors the energy changes of the ultrasonic transmission signal in real-time and combines the relationship curve between preload and ultrasonic energy to quickly and accurately determine the attenuation of bolt axial force. This method has the advantages of non-contact, real-time performance, and high accuracy, and is suitable for monitoring the connection status of bolts under various complex working conditions.

Conclusion

This study experimentally verified the nonlinear relationship between the axial force of bolts and the energy of ultrasonic surface waves and proposed an online monitoring method for bolt axial force based on the surface wave energy dissipation method. This method provides a new approach for detecting the attenuation of bolt axial force and has significant engineering application value. In the future, the experimental setup and data processing algorithms will be further optimized to improve monitoring accuracy and applicability, providing strong support for the safety and reliability of bolt connections.

Customer service 1

Customer service 1  Customer service 2

Customer service 2