Material: 7A04 aluminum rod.

Failure Background: The production of the wind cap involves main processes such as blanking, warm extrusion forming, heat treatment (quenching + aging), rough turning, finish turning, and anodizing. However, cracks appeared on the surface of the wind cap after heat treatment.

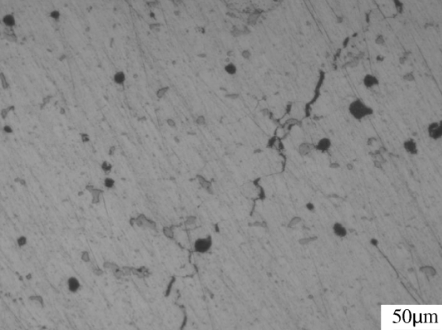

Failure Characteristics: Observation of the sample shows that both sides of the crack are clean, without metallurgical defects such as inclusions, as shown in Figure 5 - 211. After corrosion, the grain boundaries on both sides of the crack become thicker, and triangular grain boundaries and eutectic remelted globules appear.

Cause Analysis: Judging from the failure characteristics, the part has experienced over - burning. The possible causes of over - burning are as follows: First, there may be problems with the thermocouple and control instrument; second, there are issues with the furnace temperature uniformity; third, the insertion depth of the thermocouple changes, causing the actual furnace temperature to be higher than the temperature shown on the instrument. After on - site inspection, the first two items meet the process requirements. For the last item, the test results show that whether the thermocouple is inserted too deep or too shallow into the furnace, the furnace temperature is about 10°C higher than the temperature shown on the temperature - controlling instrument.

Failure Cause: The change in the insertion depth of the thermocouple makes the furnace temperature higher than the temperature shown on the instrument, and the material temperature cannot be effectively controlled. This is the main cause of the over - burning of the part.

Corrective Measures: According to the process requirements, combined with the test results of furnace temperature uniformity, fix the insertion depth position of the thermocouple. Any random change is strictly prohibited. Moreover, the operation should be carried out by a dedicated person.

Customer service 1

Customer service 1  Customer service 2

Customer service 2