In the 1970s, as aircraft design and onboard equipment became increasingly complex, issues such as high operating and maintenance costs and poor airworthiness began to draw attention in the aviation industry, giving rise to the concept of aircraft "health." Due to the numerous and complex load-bearing components, diverse mission profiles, and varied operating environments of aircraft, ensuring flight safety and managing daily use and maintenance became particularly prominent challenges.

Effectively monitoring aircraft health can enable the early detection of structural damage, cracks, and corrosion, allowing for the management and reasonable assessment of aircraft structural lifespan, thereby enhancing the economic efficiency and safety of aircraft structural design.

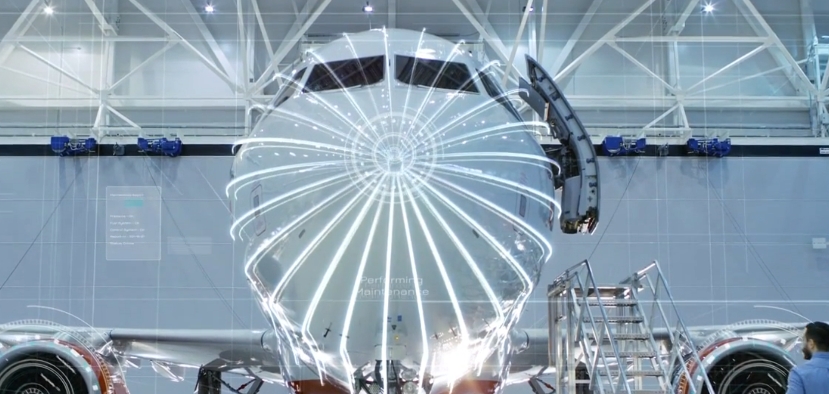

Like humans, aircraft possess their own "nervous system." Sensors act as the aircraft's "nerves," feeding back material "injury" signals collected from various parts to the server.

The server, serving as the "brain" of the health monitoring system, can not only assess the aircraft's health status but also predict potential failures and make maintenance decisions to ensure flight safety.

Monitoring in areas that are difficult for personnel to access or are inherently hazardous—such as fuel tanks, engines, or flap mechanisms—is a particular strength of structural health monitoring sensors.

On-site health monitoring sensors can detect defects more quickly, significantly reducing inspection time. Through structural health monitoring technology, aircraft maintenance time can be reduced by up to 40%.

The development of new-generation aircraft has imposed higher demands on aircraft testing, maintenance, and support, leading to the establishment of aircraft health monitoring programs during the aircraft development process.

In China, significant progress has also been made in aircraft structural health detection architecture and strategies, structural load/damage monitoring methods, structural health instrumentation, and integration. Some research findings have already played a crucial role in aircraft structural ground tests.

The application of health monitoring technology in the civil aviation sector is relatively mature, saving approximately 25% of costs associated with flight delays and cancellations. It also assists airlines in identifying recurring faults and making predictions, strongly supporting the implementation of fleet "long-term reliability plans."

As a loyal "comrade" to pilots, an effective "warrior" for safeguarding national territory, and a reliable "companion" for public travel, the aircraft is progressively moving towards智能化 (intelligence). It is believed that with the application of health monitoring systems, future aircraft will be able to sense "pain," think and decide independently, and better escort pilots to their destinations.

Customer service 1

Customer service 1  Customer service 2

Customer service 2