1、Workpiece Loading: Mount the camshaft to be machined onto the lathe's spindle and secure it in place to ensure stability.

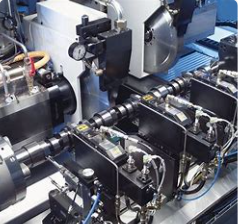

2、Cam Mechanism Setup: Adjust the parameters of the cam mechanism based on the design requirements of the camshaft, including the cam shape, position, and angle of the camshaft. These parameters determine the motion trajectory and relative positions of the cutting tools during the machining process.

3、Cutting Tool Setup: Select appropriate cutting tools and install them. The type and shape of the cutting tools are chosen based on the contour requirements of the camshaft and the machining steps involved.

4、Machining Process: Once the lathe and tools are prepared, start the lathe and control the rotation speed of the spindle and the feed rate. During the machining process, the cam mechanism transmits the motion of the cam to the cutting tools, enabling them to cut or grind the surface of the workpiece according to the contour of the camshaft.

5、Feed Control: Use the feed mechanism to control the feed speed and direction of the cutting tools as required. This helps achieve more precise machining and contour shaping.

6、Completion of Machining: By continuously controlling the motion and feed of the cutting tools, progressively machine various parts of the camshaft along its length until the desired shape and dimensions of the camshaft are achieved.

A camshaft lathe utilizes the control of the cam mechanism to drive the cutting tools to move according to the predetermined contour of the camshaft, aiming for accurate machining of the camshaft. This process requires highly precise mechanical structures, cam mechanisms, and tool setups to ensure the quality and dimensional accuracy of the camshaft.

Customer service 1

Customer service 1  Customer service 2

Customer service 2