The Impact of 3D Printing on the Mechanical Industry

Time:2023-08-30 22:54:18 Source:未知 Click:次

3D printing technology has had a profound impact on the mechanical manufacturing industry, encompassing the following aspects:

1. **Rapid Prototyping:** 3D printing provides mechanical engineers and designers with the ability to rapidly prototype. They can quickly create physical prototypes to validate design concepts and conduct functional tests, thereby reducing product development cycles.

2. **Customized Production:** 3D printing allows for the production of personalized, customized parts and products without the need for additional tooling or equipment changes. This is particularly useful for producing highly customized components, medical implants, and consumer goods.

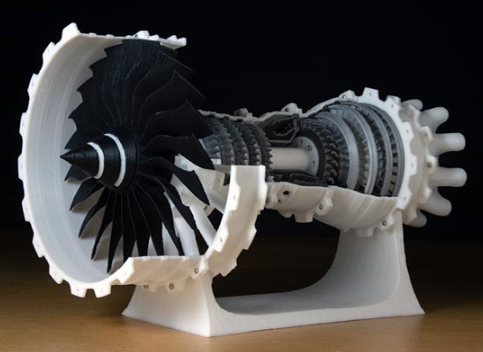

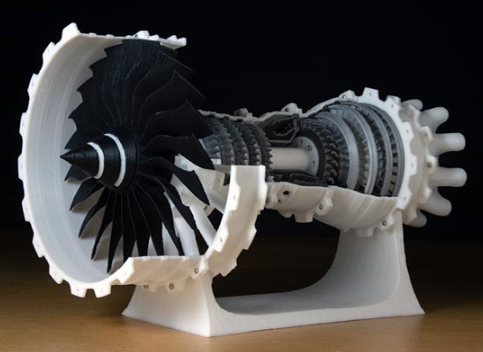

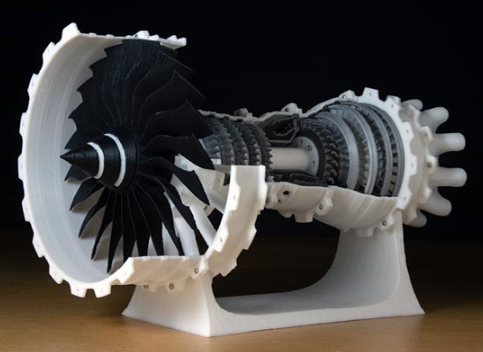

3. **Complex Geometric Structures:** 3D printing technology can manufacture complex geometric structures, including internal cavities and intricate details, which are challenging to achieve with traditional machining methods. This enables the realization of new design possibilities and lightweight structures.

4. **Waste Reduction:** Traditional machining methods often generate significant waste materials. 3D printing, being an almost zero-waste manufacturing method, constructs objects directly from the design, eliminating the need for material removal.

5. **Batch Production:** 3D printing technology is not limited to rapid prototyping; it can also be used for small-batch production. This flexibility allows manufacturers to produce small quantities of parts or products without the need for establishing expensive production lines.

6. **Supply Chain Optimization:** Manufacturers can achieve a more streamlined supply chain and reduce inventory costs by utilizing 3D printing technology. They can produce parts on-demand according to requirements.

7. **Parts Maintenance and Replacement:** 3D printing enables manufacturers to produce parts as needed, making it particularly useful for maintaining and replacing components in aging equipment, especially when original parts are no longer in production.

8. **Energy Efficiency and Lightweighting:** With 3D printing, manufacturers can design lightweight structures, reducing material consumption and lowering energy costs.

While 3D printing technology offers numerous advantages, it also faces challenges such as speed, precision, material selection, and costs. Therefore, it is often used in conjunction with traditional machining methods to maximize their respective strengths. The mechanical manufacturing industry must continually adapt to these changes to fully leverage the opportunities provided by 3D printing technology.