Tooling fixtures are essential components in the mechanical manufacturing process, responsible for holding and positioning workpieces during production. Precision tooling fixtures, particularly, play a vital role in achieving high-precision manufacturing results. This article will elaborate on the classification and characteristics of precision tooling fixtures.

Based on different manufacturing requirements, precision tooling fixtures can be divided into several types, including:

- General-purpose fixtures: These fixtures are suitable for a wide range of manufacturing fields, such as V-blocks, vice clamps, and three-jaw chucks. They possess high versatility and are applicable to different types of workpieces.

- Special-purpose fixtures: Designed for specific workpieces or manufacturing processes, special-purpose fixtures include, for example, positioning fixtures on CNC machine tools or cylinder positioning fixtures on engine assembly lines. These fixtures have high precision and specificity to meet specific manufacturing needs.

- Adjustable fixtures: Adjustable fixtures refer to those that can achieve clamping of workpieces of different sizes or shapes through adjustable structures. They include, for example, adjustable positioning blocks and adjustable vice clamps. These fixtures possess good adaptability and flexibility to meet manufacturing needs within a certain range.

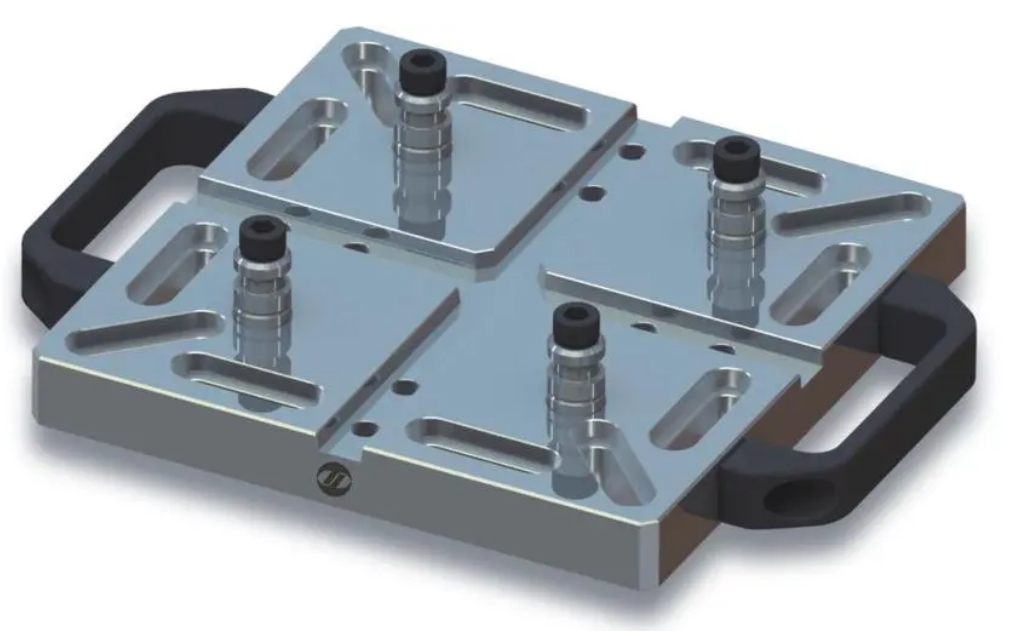

- Group fixtures: Group fixtures are designed for group processes (i.e., multiple workpieces of the same or similar processes are clamped on a single fixture). They include, for example, drilling combination fixtures and milling combination fixtures. These fixtures can clamp multiple workpieces simultaneously, enabling efficient multiple-piece manufacturing.

The characteristics of precision tooling fixtures mainly manifest in the following aspects:

- High precision: Both the manufacturing and use processes of precision tooling fixtures require high precision to ensure the positioning accuracy and manufacturing quality of workpieces.

- Wear resistance: Due to long-term use and frequent adjustments, wear resistance is an important characteristic for precision tooling fixtures.

- Reproducibility: Good reproducibility ensures stable and consistent manufacturing results for precision tooling fixtures.

- Reliability: Precision tooling fixtures must possess reliability to maintain accuracy and stability over long-term use.

Customer service 1

Customer service 1  Customer service 2

Customer service 2