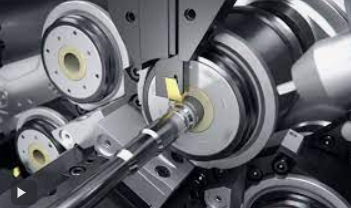

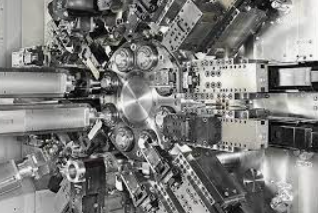

Multiple spindle automatic lathes are widely used in various industries for high-volume production of precision parts. Here are some common applications and uses of multiple spindle automatic lathes:

1、Fasteners and Screws: Multiple spindle lathes are extensively used for manufacturing fasteners such as bolts, screws, nuts, and studs. The simultaneous operation of multiple spindles enables efficient threading, chamfering, and head formation, resulting in high production rates.

2、Automotive Components: Many automotive parts require high-volume production and precise machining. Multiple spindle lathes are used to manufacture components like shafts, pins, connectors, valves, fittings, and other small-to-medium-sized parts used in engines, transmissions, suspension systems, and fuel systems.

3、Electrical and Electronics: Multiple spindle lathes are employed in the production of electrical and electronic components, including connectors, terminals, pins, sockets, and switch components. The machines can handle various materials like brass, copper, aluminum, and plastic, meeting the demands of the electronics industry.

4、Medical Devices: The medical industry requires precision parts in large quantities. Multiple spindle lathes are utilized to manufacture medical components like surgical instruments, orthopedic implants, dental tools, and medical device parts. The ability to perform multiple operations simultaneously ensures high efficiency and accuracy.

5、Aerospace Components: Aerospace manufacturing requires high-quality and complex parts. Multiple spindle automatic lathes are used to produce components like valves, fittings, bushings, and connectors used in aircraft engines, landing gear, and hydraulic systems. The machines can work with materials such as titanium, aluminum alloys, and stainless steel.

6、Plumbing and Fittings: Plumbing fittings, valves, and connectors for various industries are commonly produced using multiple spindle automatic lathes. The machines can efficiently machine threads, create precise shapes, and perform drilling and tapping operations on materials like brass, stainless steel, and plastic.

7、Hydraulic and Pneumatic Components: Multiple spindle lathes are utilized to manufacture hydraulic and pneumatic system components like pistons, cylinders, connectors, and valves. These components require tight tolerances and high precision to ensure smooth operation and reliable performance.

Overall, the usage of multiple spindle automatic lathes is widespread in industries where high-volume production, precision machining, and efficient operations are essential. These machines play a vital role in meeting the demands of various sectors by delivering consistent quality, productivity, and cost-effectiveness.

Customer service 1

Customer service 1  Customer service 2

Customer service 2