A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.

Compared with a jig

A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary.

Purpose

A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working time by allowing quick set-up, and by smoothing the transition from part to part.[3] It frequently reduces the complexity of a process, allowing for unskilled workers to perform it and effectively transferring the skill of the tool maker to the unskilled worker.[2] Fixtures also allow for a higher degree of operator safety by reducing the concentration and effort required to hold a piece steady.

Economically speaking the most valuable function of a fixture is to reduce labor costs. Without a fixture, operating a machine or process may require two or more operators; using a fixture can eliminate one of the operators by securing the workpiece.

Design

Fixtures should be designed with economics in mind; the purpose of these devices is often to reduce costs, and so they should be designed in such a way that the cost reduction outweighs the cost of implementing the fixture. It is usually better, from an economic standpoint, for a fixture to result in a small cost reduction for a process in constant use, than for a large cost reduction for a process used only occasionally.

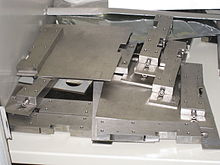

Most fixtures have a solid component, affixed to the floor or to the body of the machine and considered immovable relative to the motion of the machining bit, and one or more movable components known as clamps. These clamps (which may be operated by many different mechanical means) allow workpieces to be easily placed in the machine or removed, and yet stay secure during operation. Many are also adjustable, allowing for workpieces of different sizes to be used for different operations. Fixtures must be designed such that the pressure or motion of the machining operation (usually known as the feed) is directed primarily against the solid component of the fixture. This reduces the likelihood that the fixture will fail, interrupting the operation and potentially causing damage to infrastructure, components, or operators.

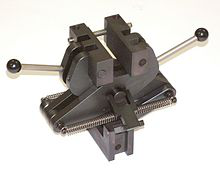

Fixtures may also be designed for very general or simple uses. These multi-use fixtures tend to be very simple themselves, often relying on the precision and ingenuity of the operator, as well as surfaces and components already present in the workshop, to provide the same benefits of a specially-designed fixture. Examples include workshop vises, adjustable clamps, and improvised devices such as weights and furniture.

Each component of a fixture is designed for one of two purposes: location or support.

Customer service 1

Customer service 1  Customer service 2

Customer service 2