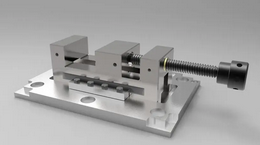

A jig is a specialized tool or fixture used in manufacturing, woodworking, or metalworking processes. It is designed to guide, support, and hold the workpiece in a specific position, allowing for accurate and repeatable operations. Jigs are commonly used to ensure precise and efficient production by guiding the tools or machinery during various tasks such as drilling, cutting, shaping, or assembling.

The main purpose of using a jig is to improve accuracy, consistency, and productivity in manufacturing processes. By providing a predefined template or guide, jigs help eliminate errors, reduce setup time, and enhance the overall quality of the finished product. Jigs can be simple or complex, depending on the specific operation they are designed for.

There are different types of jigs used in various industries, including:

-

Drill Jig: Used for guiding drills during hole drilling operations, ensuring precise hole placement and alignment.

-

Router Jig: Utilized in woodworking for guiding a router during cutting or shaping operations, allowing for consistent and accurate results.

-

Welding Jig: Used in metalworking to hold and align workpieces during welding processes, ensuring proper joint fit-up and alignment.

-

Assembly Jig: Employed in manufacturing to aid in the assembly of components, ensuring correct positioning and alignment.

-

Template Jig: Provides a template or pattern for shaping or tracing specific profiles or contours onto workpieces.

Customer service 1

Customer service 1  Customer service 2

Customer service 2