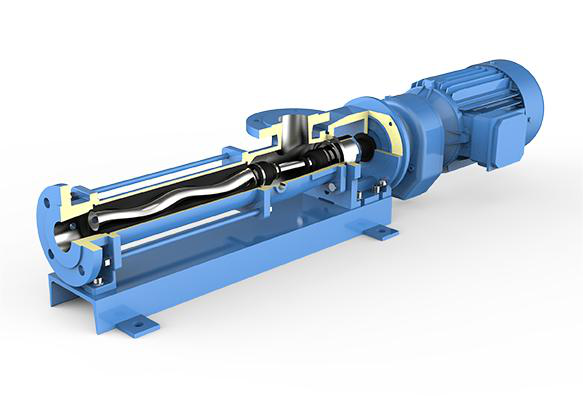

Subsequently, under the action of the screw, the liquid is smoothly pushed towards the pump's outlet. Due to the close fit between the screw and the pump casing, an efficient closed chamber is formed. The liquid is compressed within this sealed chamber and discharged from the outlet. Throughout this process, the single screw pump can provide a stable flow rate with minimal pulsation.

Advantages of Single Screw Pump:

1. High Efficiency and Stability: The single screw pump can provide a stable flow rate with minimal pulsation.

2. Wide Adaptability: It can handle low to medium viscosity liquids and is also suitable for high viscosity and high concentration fluids such as pastes, colloids, and multiphase fluids.

3. Strong Handling Capacity: The single screw pump can handle liquids containing solid particles and has strong conveying capabilities.

4. Efficient Sealing: The close fit between the screw and the pump casing ensures efficient sealing, ensuring the pump's performance and safe operation.

5. Wide Range of Applications: The single screw pump plays an important role in various industries, including industrial, agricultural, chemical, petroleum, and food sectors.

Possible Faults and Maintenance Methods for Single Screw Pump during Use:

1. Leakage: Leakage at the pump body seals and inlet/outlet pipes can be resolved by checking for loose or worn seals and tightening or replacing them.

2. Excessive Noise: Excessive noise during operation may be caused by screw wear or bearing failure. Check the screw for wear and replace it promptly.

3. High Temperature Rise: Prolonged operation without proper cooling or lubrication can lead to excessive temperature rise. Take necessary cooling measures or add lubricants to prevent overheating.

4. Motor Failure to Start: In the case of motor failure to start, check the power supply for faults first to rule out power-related issues. Then, inspect the motor for any damage and proceed with repair or replacement if necessary.

Customer service 1

Customer service 1  Customer service 2

Customer service 2