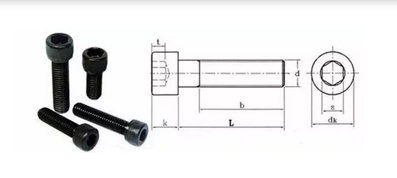

If you look closely, you'll notice that 99% of the flat-pack furniture bought online uses hexagonal socket screws. The head of the hexagonal socket screw is round on the outside with a concave hexagonal shape in the middle. This structure actually has quite obvious advantages.

Greater Load-bearing Capacity

The hexagonal socket screw has six load-bearing surfaces, which can withstand more twisting force compared to slotted screws and cross-recessed screws, which only have two surfaces.

Superior Anti-slip Performance

The hexagonal structure of the socket screw provides higher friction between the screw and the tool, making it less likely to slip even when lateral force is applied during tightening or loosening. This allows workers to perform operations more accurately and quickly, improving work efficiency.

Higher Aesthetics

The smooth appearance of the hexagonal socket screw makes it more aesthetically pleasing in various products. Compared to slotted and cross-recessed screws, hexagonal socket screws are easier to surface treat, such as galvanizing or chrome plating, which enhances the overall texture of the product and aligns more with modern aesthetic standards.

Convenient for Automated Production

The structural characteristics of the hexagonal socket screw make it more suitable for automated production lines. Due to the unique shape of the hexagonal socket screw head, robotic grippers can easily identify and pick it up, improving production efficiency. Additionally, the installation process of the hexagonal socket screw requires minimal adjustment, which helps achieve high-speed operation of the production line.

Space-saving

The head design of the hexagonal socket screw is more compact, which can save space to some extent compared to other types of screws. This is particularly important in precision instruments and electronic products, helping to reduce the weight and cost of the product.

Easy Maintenance and Replacement

During the process of disassembling and installing hexagonal socket screws, the unique hexagonal structure makes it easier for workers to judge the tightness of the screw. Moreover, hexagonal socket screwdrivers are common in the market, making it convenient for maintenance personnel to quickly find the right tool for operation.

Strong Adaptability

Hexagonal socket screws are suitable for a variety of materials such as metal, plastic, wood, etc., demonstrating high adaptability. This has led to their widespread use in various fields, including construction, furniture, electronic products, and more.

In summary, thanks to its numerous advantages, the hexagonal socket screw has been widely used in many fields. As industrial production continues to develop, the market demand for hexagonal socket screws will continue to grow. For consumers, understanding these benefits of hexagonal socket screws can help them pay more attention to product quality and performance when choosing furniture, electronic products, and more.

Customer service 1

Customer service 1  Customer service 2

Customer service 2